Efficient For Fine Grinding Of Several Ores And Different Minerals.

Efficient For Fine Grinding Of Several Ores And Different Minerals.

When most people think of milling machines, they imagine a vertically oriented machine that comprehends rotary cutters. Traditional milling machines such as this are widely used in the manufacturing industry to redesign work pieces. However, there are many other types of milling machines, one of which is a ball mill. What is a ball mill exactly, and how does it differ from traditional milling machines?

What is a Ball Mill?

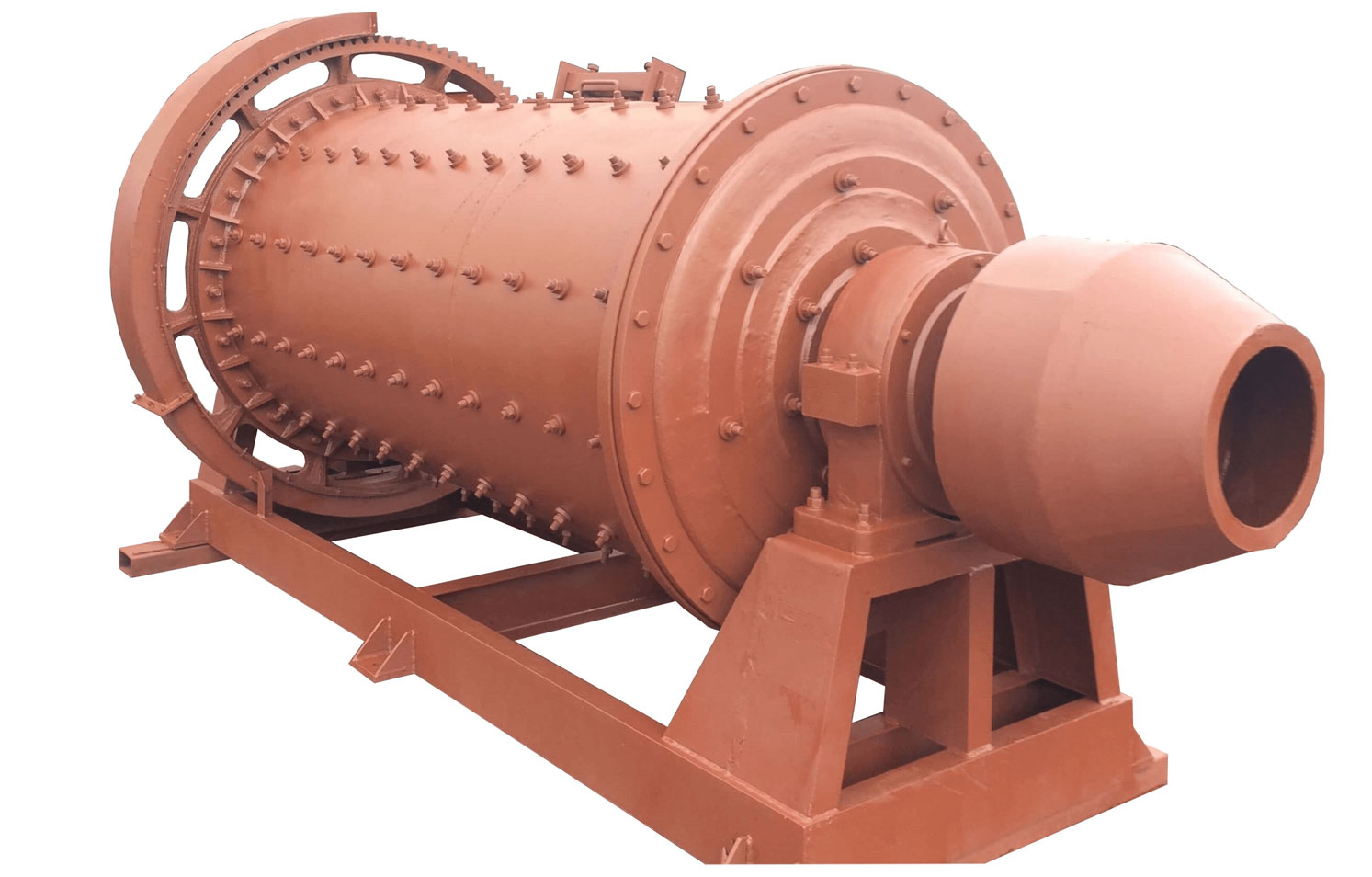

Ball mill is a kind of grinding machine that uses balls to grind and remove material. It contains a hollow compartment that rotates along a horizontal or vertical axis. It’s called a “ball mill” because it’s literally filled with balls. Materials are added to the ball mill, at which point the balls knock around inside the mill.

Working principle of a Ball Mill

Ball mills function by using balls to grind materials. Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is triggered so that it rotates — either on its vertical or horizontal axis. As the ball bill revolves, the balls bounce around while striking the enclosed material. The force of these strikes helps to grind the material into a finer, less-coarse medium.

For a ball mill to function, critical speed must be attained. Critical speed refers to the speed at which the enclosed balls begin to rotate along the internal walls of the ball mill. If a ball mill fails to reach critical speed, the balls will remain stationary at the bottom where they have little or no impact on the material.

Ball Mills vs Traditional Milling Machines

Ball mills differ from traditional milling machines in numerous ways. First, ball mills don’t have a cutting tool. While traditional milling machines depend on a rotary cutting tool, ball mills leverage the force of moving balls to perform their operation. As a result, they don’t require a cutting tool.

Another difference between ball mills and traditional milling machines lies in their particular function. Both ball mills and traditional milling machines are designed to remove material. However, traditional milling machines support huge work pieces, whereas ball bills support materials like ore, ceramics and paint. The material is added to the ball mill’s compartment, at which point it’s exposed to the rotating balls. This influential rotation grinds down the material into a finer, powder-like medium.

Conclusion

Raymer Engineering Corporation is a one-stop destination for purchasing the high quality of Ball Mills. Here, you can discover an extensive range of Ball Mills. As a leading manufacturer and supplier of Ball Mills, we are devoted to quality. Our entire range of milling machines is manufactured using refined techniques by our expert human resources. The machine is made of premium parts and state-of-the-art inventions following industry quality standards.

If you are planning to purchase Ball Mills, then we have the answer to what you are looking for. At Raymer Engineering Corporation, we supply top-performance Ball Mills that will suit your milling needs. All you need is to contact us via phone or email and we will tell you everything, including the price of Ball Mills.

Recent Comments